|

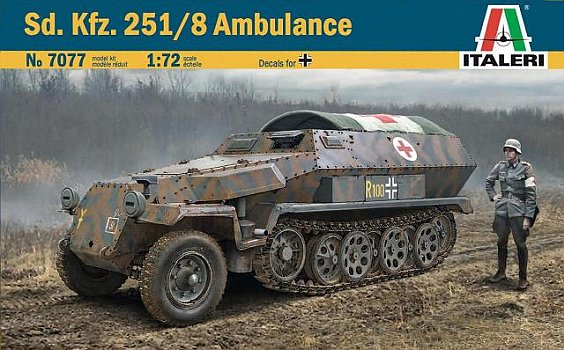

In late 2019 I

received from Italeri a preproduction sample of their Sdkfz 251/8

which was going to be released in early 2020.

The kit is the old ESCI one of which I'm familiar, having made some

of them in the '70s. The hull variant proposed by the kit is the riveted

Ausf. C. As far as I've found, this variant was built only by Boehm

Leipa, a Czech company which initially couldn't weld the steel plates

so in the meantime they produced the hulls by riveting.

The moulds I received were light grey (when I made my ESCI versions

in the '70s, they were dark grey) while the link and length tracks

mould were in a strange, semitransparent white plastic. Production

kits will have metallic grey plastic. Luckily there is no trace of

the terrible soft plastic tracks one found in the '70-'80s releases.

Production kits will also have instructions and a decal set. I've

found images of both surfing on the net. There are also two figures,

an officer and a soldier who should be placed behind the forward MG.

The halftrack is split in three sprues. On two of them there are the

basic pieces to make the generic vehicle. Despite this, the tools

are separate parts, something that's ignored on more recent kits.

The way ESCI attached the hull to the sprue poses a problem: the sprue

attachments lie on the riveting lines and this means that careful

cleaning is needed. Despite this, some riveting will be surely lost.

A solution could be converting it to a welded hull, though the conversion

shouldn't be limited to just erasing the riveting. The hulls weren't

identical and some differences can be immediately seen in the air

outlets on the bonnet, or the overlapping upper hull.

The fourth mould has two stretchers, a single seat, two straight rods

and four tarpaulin supports. There is also a barrel. On the Italeri

instruction it is omitted, while it was present in the original ESCI

one. I've seen very few 251/8 photos on which the barrel was present,

just on a halftrack captured by British soldiers in North Africa and

actually exposed at Bovington.

ESCI at its time, and now Italeri, aside from the 251/1 troop carrier,

can put on the bench some different sub variant adding a fourth specific

mould to the two generic ones:

251/1 with rockets launcher

251/7 engineer

251/8 armoured ambulance

251/10 with a 3,7cm PAK

251/16 with flame thrower

As references I used the Squadron Signal SdKfz 251 in Action: Armor

No. 21, and the Sturm & Drang no. 3: SdKfz 250 & 251.

| |

Real |

1/72 |

kit |

| Length |

5,800 |

80.6 |

81.5* |

| Width |

2,100 |

29.2 |

31.3** |

| Height |

1,750 |

24.3 |

24.8 |

| Wheels |

190x18 |

12.2x3 |

11.0x2.6 |

| Track

width |

280 |

3.9 |

4.6 |

(for * / ** see text below)

General dimensions are almost correct being about 2 mm wider. Also the

tracks are too wide, but at the end the thing is not so perceptible.

About the width, if I'm right, the overall width

is 2.1 mm wider (** I measured it out of the tiny moulding running

along the edge) and the naked hull (using a 1/35 scale drawing as

reference) is 1.0 mm wider. This means each mudguard is just 0.55

mm too wide, but not evenly. The forward part (around the wheels)

is more correct, but going backward the width grows and reaches the

maximum at the rear corners.

The model has little discrepancies on the nose area (lower hull),

the rear hull angles and on the mudguard shape. Anyway the overall

shape looks well as depicted and these are not perceptible.

A critical point of this kit would be the interior which is very poorly

rendered. About this there is something to say. The rear compartment

was often closed by a tilt laying over the arched supports. If one

wishes to make his model in this way, the first part of my review

is useless and he can jump directly to the exterior part. I have made

a choice regarding the interior. I choose to ignore a detail common

to every riveted vehicle: on the inner side of each riveted plate

there was a flat rod with each rivet other head. I'm not so finicky

at the end. I detailed the driving compartment not knowing what could

be seen after having closed the hull. Well, the answer is very little.

But I have no regrets; it's part of the modelling enjoyment, I think.

Interior

- I

had to file off a part of the ridge (see picture 1 below) present

on the lower hull inside to allow a correct placement of the floor.

- The

four mudguard interlock holes are very visible. I filled them using

plastic and cyanoacrylate glue. The two in the engine compartment

will be hidden by the firewall.

- The

floor interlock for the firewall interferes with it. It needs to

be modified for a correct fitting.

- The

steering wheel wasn't placed as normal. It was placed turned at

90°. I made a new support and glued the wheel in the correct

position.

- The

bolted part of the unused piece 41A gave me the idea to use it to

make something which could imitate a radio in the shadow of the

interior (see picture 3 below).

- I

glued a circular piece to the water-barrel above the gearbox (a

251/8 feature) to give the idea of a rounded item.

- The

seats are undersized, I replaced them with plastic and metallic

wire (see picture 2 below).

- I

added the flange just behind the driver seat which keeps the forward

half to the rearward half together.

- I

added the four interior parts of the armoured visors by plastic

pieces. They are not heavy detailed because they will be barely

visible.

- Using

plastic pieces, I made the bin, the cases for the spare armoured

glass, and the MP40 magazine housings.

- The

MP40 was glued at the radio operator station.

- I

engraved the rod of the sledges for the stretchers. The lower sits

a bit too high and doesn't allow the presence of a wounded soldier.

I filed the shims. On the wall aside the stretcher there were three

panels not visible at hull closed. I ignored them.

- I

didn't understand how the upper stretcher would stay in place following

the instruction. In real life it was hinged to the outer side and

two chains secured the inner side to the transversal straight rods.

To make the hinges I found the unused door hinges useful (see picture

5 below). Their dimensions are quite exact and the gluing edge was

filed to reach the hull plate inclination. To have a horizontal

position I glued the two parts on a glass. The chains were enclosed

by a flexible rubber pipe. I made them using stretched sprue; the

exposed first rings were made by thin metallic wire.

- The

foldable single seat was placed on a hinge glued to the wall. It

had a foldable support.

- The

benches were foldable and I used them without modification, adding

just the hinges. On the photo I've seen, the forward bench look

as long as the stretcher.

- Using

stretched sprue I made the locking system on the starboard door.

- And

the best for last. The rear door hinges were something very different

to the "L" shaped affairs given in the kit. Four vertical rods connected

by four bent rods coupled by four smaller rods. Patiently I rebuilt

the hinges withstretched sprue. They are not as detailed as the

originals, anyway now they look more realistic (see picture 4 below).

Exterior

- Some

trimming was needed for a correct alignment of the hull front where

the plastic was a bit in excess (possibly not a problem on production

kits).

- The

thickness is huge on piece 40A (radiator cover). I filed its edges

and the hull corresponding to have a 45° joint. Its hexagonal

shape is not correctly depicted being a bit narrow on the folded

edge, but to correct them requires altering the lower hull and making

a new piece with riveting. Another easy to do correction: I rounded

the transition line between the hexagon part and the lower rectangular

part by sanding. The original part was a single bent piece, not

two riveted or welded together. These correction made the length

correct for the 1/72 scale (see table above).

- At

the sides of the front there were two hooks. I made them with metallic

wire shaped by a file and sand paper (see pictures 6 & 7 below).

- The

lateral visors were smaller than the frontal ones. Furthermore they

were placed too far forward. I carefully removed them to be replaced

by scratch built parts by shaping a sprue segment, not a masterpiece

but no worse than the moulded ones. The double vertical rivet lines

were lost. Nothing major. These were placed at the side of the joint

line which runs below the roof edge, so their position is too much

rearward. I engraved the joint.

- The

bullet splash guard doesn't always appear on the photos I've seen.

Being unarmed, the thing looks logical, I didn't find an explanation

but what I can suppose is that some troop carriers were converted

or taken from the production line. I left it in place after having

carefully sanded two sinks in the rear part of the roof. I also

used stretched sprue segments to make the plugs for the MG unused

supports.

- I

fashioned the handle on the edge of the roof using metallic wire.

- The

lower part of nose is not correctly depicted. I didn't find a photo

or a blueprint of an Sdkfz 251 underside and the few photos I've

seen of this area showed another layout. I used a 1/35 Dragon kit

as guide because it looked to match the photo. Without going crazy,

I removed the boxes and replaced them with two pieces of plastic.

One shaped as the engine belly and the other as the sprockets transmission

cover. This didn't restore at 100% of the original, anyway

now it looks better than before (in my opinion).

- The

front axle suspension is too much spaced and the wheel muzzles are

placed on the lower edge instead in the middle. I cut the piece

in four parts and reshaped the suspension. It is also placed 1 mm

forward. I filed the interlock and repositioned it.

- The

wheels are just a bit undersized. If one has a couple of spare tires

they could be replaced. The rim has two concentric edges. The outer

is 7.5 mm and the inner is 6.5 mm, which is more correct for an

18" rim.

- I

added, using stretched sprue, the steering rods, one between the

wheels and another along the hull side.

- The

"V" shaped stabilizer for the transversal suspension system is not

well depicted. I made it by stretched sprue.

- The

track wheels had a torsion bar suspension system. I added the arms

from plastic strips.

- The

central track wheel row should be composed of two separated wheels.

If one wished they could engrave the rubber thickness. I didn't

in a moment of laziness. The outer wheels have the holes a bit smaller

and too near to the hub. There is nothing to do about but replace.

I kept them.

- I

added the hub covers which are absent in the sprockets, the wheels

and the idlers, using plastic rods.

- The

tracks miss the central guide teeth and are 0.7 mm wider. I left

them as they are.

- The

mudguard front flaps are too long; I filed them to the correct length.

The first time I measured them in the nose area and then I realized

too late that they are not parallel. As already mentioned earlier,

their overall width grows. Too late. If I had realized this earlier

I could have filed off 0.5 mm on the rear inner side. To keep them

parallel I modified them with a 0,5 mm shim near the engine area.

- During

the cleaning of the mudguards part of the edge was lost. I replaced

it by thin stretched sprue.

- On

the forward corners, I made the width indicators using metallic

wire and a drop of glue.

- The

bins on the mudguards are pushed too much inside: their doors opened

downward hanging vertically. I realized the problem after having

glued them, so I replaced the doors with plastic. I could also shim

the inner side. I also replaced the locks which were placed over

the bins.

- As

for the shovels, they look better if the blades are bent downward,

being aligned to the handles.

- For

a proper placing, the track sub-assemblies were glued after having

placed the mudguards. If glued first, the front of the track could

touch the mudguards. This meant I had to reshape in place the rear

edge of the pieces 58A and 59A.

- When

the tracks were placed, the rear of the hull gave me a strange look.

After a little research I found the reason. The plate under the

hook is too high, because the belly wasn't straight. From the last

track wheel to the idler it was sloped. I reshaped them and the

look is greatly improved (in my opinion).

- I

shortened the towing hook overhang, looking too prominent. After

having glued in place, I cut it off. After having drilled the square

base I glued the shortened hook which was also slightly enlarged

by stretched sprue.

- I

added, using plastic strip and stretched sprue, an antenna base.

- The

arched supports for the rear compartment cover can be omitted or

used covered by a scratch built cover. I chose to use them, but

as their thickness is excessive, I thinned them before gluing in

place.

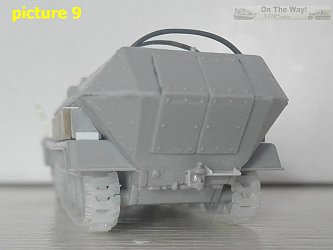

- A

251/8 feature missing in the kit is the step under the starboard

door. I made it by plastic sheet and stretched sprue (see picture

9 below) .

Decals

The sample I received didn't come with decals. Production kits have

a well detailed set for three armoured ambulances. I couldn't be sure

about their correctness because I didn't find the photos of the original

vehicles, but I found photos of vehicles which could be.

- WH1262755,

R100, a Stab. Pz.Div. 16 in Russia, 1942. I don't know if this is

referred to the same photos I have. If so in my sources the divisional

markings are not visible and it was an Ausf. B.

- WH1264768,

Stab. Pz.Div. 21 in North Africa, 1942. Quite generic, I didn't

find its specific photo.

- no

plate number, unknown unit, Russia, 1942. As for R100, I found a

photo of a 251/8 which looks like the depicted vehicle (it's hard

to say without the plate numbers) but this too is an ausf. B.

Conclusion

At the time ESCI released their Sdkfz 251s they were the only in 1/72

plastic kit and they looked good (old rubber tracks apart). Currently,

more precise and detailed (though not perfect) moulds by Dragon and

Revell make this a simplified kit in comparison, placing it at an intermediate

level. Despite this, if one is not scared by the old school way, with

some white plastic added here and there, and the needed care, it can

still be made into a quite good display model, if one can live with

the wider dimensions (that if one works on the mudguards is limited

to 1 mm). About the interior, my job at the end resulted in an almost

futile exercise because very little resulted visible after having closed

the hull.

On the other hand, while Dragon and Revell have every other variant

of the introduction list, currently this is the only /8 and its specific

parts could be used with another kit to make an ausf. C welded hull

or an ausf. A, B or D, making this kit useful in another way.

Review sample supplied by Italeri.

Italeri

products are available at

|