| This

is one of the more British style vehicles one can see in a WW2 photo.

For a long time, the only way to have a Universal Carrier in small

scale plastic kit was modeling the Airfix HO/OO kit, which is even

smaller than 1/76 and needs a lot of work.

In recent years the IBG kits filled this gap with no less than four

very well done kits, each one being a different variant (Mk I, Mk

II, Mortar carrier Mk II and Boys AT Mk I). PSC arrived with a quick

building kit, which reflects the philosophy to have multiple simplified

models. Three Carriers are given without decal set. It is a cheap

and simple solution.

In my opinion the only really negative point shared by both manufacturers

could be about the wall thickness (but to have them in the right scale

they should be done with PE parts). Anyway on the later production

the problem is felt only in the driver compartment because the rear

compartment had a rounded handrail to protect the crew from the edge.

Thinning them is not as easy as one can think. If correctly thinned

the finished interior would have spacing at the engine cover and the

compartments division endings. Moreover if the plates are replaced

with thin plastic sheet the tiny surface details would be lost. If

the plates are thinned only on the upper edge, the finished look would

not be as good as one may wish, with a triangular section well visible

in the corners. At the end I kept them as they are (for both IBG and

PSC).

The PSC kit gives us the parts to make both Mk Is and Mk IIs, but

doesn’t have the towing hook.

About that, I found a bit confusing fact. Most of the sources I consulted

states the Mk II had the towing hook while the Mk I didn’t.

Anyway I found some photos of Mk IIs without the towing hook (and

few photo of Mk I with the hook, like T79484 or Mortar CT163736).

It means PSC is not exactly wrong for this.

On the other hand, in a 1/72 perspective the main differences we can

list between the two Marks are about:

- The

different mudguards skirts

- The

different front lights layout

- The

different stowage bin on the rear plate

The Mk

I rounded bent mudguard skirts were associated to the double lamps,

but already in the Mk I batch CT199801-CT201800 there are Carriers

which shows the later single lamp at left. Also T132812, a Mk I Mortar

carrier of the T132736-T133149 batch, had this lights layout, but

I don’t have other photos of this batch. The Mk II squared stiffened

skirts were used at least by the T202177 - T203776 batch onwards.

I don’t have a photo of a Mortar Carrier of the CT201801 - CT202100

batch, which could be based on the last Mk Is or on the first Mk IIs.

Dimensions of the assembled kits are quite correct and the comparison

between the 1/72 kits reveals they are very similar:

|

|

1/72 |

PSC |

IBG |

Length |

12ft

|

50.8mm |

50.1mm |

51.4mm |

Width |

6ft

9in |

28.6mm |

27.2mm |

27.2mm |

Height |

5ft

2in |

21.9mm |

21.0mm |

20.3mm |

And if

someone is wondering about the Airfix kit:

|

|

1/76 |

Airfix |

Length |

12ft

|

48.0mm |

47.1mm |

Width |

6ft

9in |

27.0mm |

25.0mm |

Height |

5ft

2in |

20.7mm |

18.6mm |

To make

my models I had to try to understand a bit more about the Universal

Carrier variants (ignoring the former Carrier types as well as the

overseas production types) because 113,000 were produced and some

differences were made along the production. What I’ve found

is that the little Carrier tree had more branches one can imagine.

Again I had some difficulties to understand the British nomenclature,

also because there are some little differences between one source

and another.

The Universal Carrier was made in three Marks: I, II and III. A number

before “Mk” means the engine type: No.1 (65 hp), No. 2

(85 hp), No. 2A (85 hp) and No. 3 (95 hp). A star (for example No.

3 Mk II*) meant a Canadian built carrier.

It should be simple, but I didn’t understand if each Mark was

produced with every engine type: the cover of the April 1944 Service

instruction book (photo found on MLU forum), shows only the following

types:

- Carrier,

Universal Mk I

- Carrier,

Universal No. 1, Mk II

- Carrier,

Universal No. 2, Mk I and Mk II

- Carrier,

Universal No. 3, Mk II

Aside

the Universal configuration, there were three official variants: the

Carrier, Armoured, Observation Post; the Carrier, 3” Mortar

and the Carrier, Medium Machine Gun.

Always referring to the April 1944 Service instruction book, the list

is about:

- Carrier,

3” Mortar No. 1, Mk I and Mk II

- Carrier,

3” Mortar No. 2, Mk II

- Carrier,

3” Mortar No. 3, Mk II

- Carrier,

Armoured, Observation Post No. 1, Mk I, Mk II and Mk III

On this

cover (I don’t have the book) the Mk III is referred only to

the AOP variant, but in other sources the Mk III is referred also

to the Universal carrier type. Although some sources I found say that

starting from the Mk II the hull was welded, I think this could refer

to the lower hull, because photos clearly show the riveting on the

upper hull sides, at least for the following batches: T202177 - T203776,

T208740 - T210400, T223384 - T223983, T226038 - T228466, T252505 -

T253123, T274035 - T274648, T275608 - T276638. I didn’t find

a photo of a Mk II with the welded upper hull. The kit plates are

riveted; as far as one can correctly expect, the inner sides should

show the inner structure of bolted “L” rods which keeps

the whole together, but they are completely flat and no details are

given by both kit makers.

The welded hull was certainly used by the Mk III. In the April 1944

Service instruction book the welded Mk III is called Mk IIIw (such

as for the Cromwell Mk Vw). In the MAFVA census number list, there

are only one UC and two AOP batches named as Mk III. The UC T331701

- T334900 batch was cancelled and not produced (“Universal carrier

1936-1948” by D. Fletcher) while two other batches ordered as

Mk II (T272101 - T272884 and T339801 - T340408) were produced as Mk

III. On the basis of the differences found from the former marks,

the Mk III had a new engine cover with a different air inlet and a

new transversal division plain plate (which is more visible in photos)

without the large rectangular slots just above the forward seats.

If this is the rule, also the batch T245780 - T249540 which is identified

as Mk II in the MAFVA list should be Mk III. The batches produced

as UC were made when the standard was the Mk II, so they had the same

skirts, lamp and rear bin. The AOPs were made when the standard was

the Mk I and had the same skirts and rear bin while a single lamp

was placed on the glacis.

Speaking about how to have something a little more different, apart

fom the production wheels with narrow “T” section spokes,

I’ve seen two variations. A first variation had a concave plain

centre with six large rounded holes (see for example T274089 or T253118);

the second one had larger spokes (see for example CT43325 or T202226).

As far as I’ve seen up till now these two types look to be used

as replacement and not as production line set.

I didn’t study the early production Carriers in detail, so it

is possible that I ignored some details or that some comments about

them are not pertinent.

Other minor layout differences look to be given by the crew role;

see here: http://www.vickersmachinegun.org.uk/transport-universal.htm

.

To add other modelling possibilities, home made bins or racks or arrangement

alteration added at the unit workshops can be seen in the original

photos, see for example the airborne Universal Carriers.

Also the Russians lend-lease vehicle and the German captured Carriers

give us opportunities to model different subjects. For some useful

Beute Bren Carrier (e) photos see here.

Speaking

about some reference on the web between others, a couple of useful

walkaround are here:

A useful

information source can be found here.

And useful photos here.

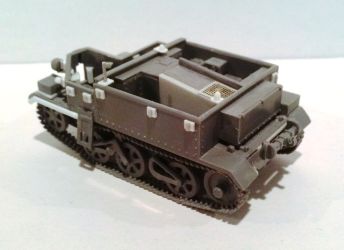

The

PSC kit

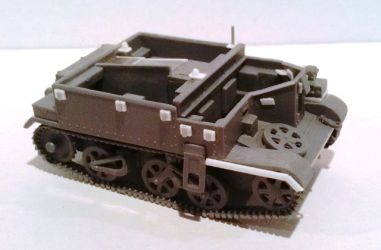

The look

of the mouldings gives a sober impression, only 27 pieces composes

the vehicle set (comprising the optional parts and the large roll);

some details are not very finely sculpted and the wheels and tracks

sets are solid single pieces.

Coming from the war games world, this kit has the crew (very well!).

The two figures for the driving compartment are a bit stiff, while

the rear compartment figures relaxed pose are more convincing, however

they are moulded for a Carrier stripped of the usual items stowed

in the rear compartments. The heads are given as separate parts. This

is positive: the faces are moulded from the front; the head can be

slightly turned and can be easily swapped. The PSC heads look to me

too much near the chest so I shimmed the neck a little.

I added some basic details to my kit. Here is what I did to have a

Universal Carrier Mk II in Normandy:

Hull

- The

poorest detail of this model is the solid over simplified exhaust

area. I filed away the “box” with the moulded on the

transmission axle which fills the area, keeping just the differential

housing. I closed the wall with thin plastic sheet and then I added

the details. The axle was made with plastic rod while the exhausts

were made with stretched sprue.

- I

drilled the holes in the front towing points moulded on the glacis,

which were also thinned.

- I

thinned the exposed fender thickness.

- The

mudguard skirts were sometimes removed, but the tracks miss their

external details where the skirts have to be glued making their

use compulsory.

- The

hole for the Bren gun could be closed with a simple rectangle when

the gun wasn’t used. If the Bren is to be installed, a replacement

is recommended.

- The

spare wheel could be fixed with a large roundel as for the kit,

or with a little rectangular shaped plate. I changed it but the

kit detail can be kept as it is.

- The

Mk II rear bin was heightened with thin plastic sheet.

- Mk

II sides could have two further steps just in the mid of the rear

compartment. The kit doesn’t give them, but this is not a

problem because they don’t look to have been widely used.

- The

Mk II single light is huge. I replaced it with a scratchbuilt one

made with sprue sections and then I detailed it with its support

and its thin metallic wire.

- On

the front there also were smaller lights; they were added (with

their supports) using plastic rod shaped as a half egg.

- A

simple improvement can be made adding the deep wading kit interlocks.

These were thick rectangular plates, with a pipe segment welded

on and bolted to the hull sides. I made them with plastic and stretched

sprue. The full deep wading kit is quite easy to scratchbuild and

is a good way to have something different from the models proposed

by the manufacturer added an IBG towing hook which was in the spares

box. As already seen, its absence is not really a problem.

- On

the front plate there was a short horizontal closed pipe. It was

access for the starting handle. I drilled the hole where it will

be glued after the driver compartment will be closed because the

upper millimeter of the plate is the glacis thickness and the surface

will be sanded smooth.

- The

glacis overhangs the front plate a little. I added this with a thin

stretched sprue segment.

Interiors

- In

the photos I’ve seen the left side of the engine cover was

vertical. To correct this I placed a new side widening the kit deck

at left. This means I lost the riveting row. I’m not so clever

to make a new one.

- I

made the instrument panel with a piece of plastic from the thick

squared sprue.

- I

also added the inner shutters of the vision slots made with very

thin plastic sheet.

- The

inside is very empty. Some bins and some boxes are needed to fill

the driving and the rear compartments. Inspiration was found in

photos.

- I

also added the shelves for the antenna bases.

- I

also added an IBG wireless apparatus left from the mortar carrier

kit

- With

plastic rods I made the two fire extinguishers. They were of the

brass colour types which were placed at the sides of the Bren gun

mount (the handle was “T” shaped but after having had

a nervous collapse I left it alone as you can see. I know, the vertical

arm is missing).

- Also

the support for the Bren gun was made with plastic.

- In

the co-driver area I added the shelf for the 2” mortar.

- The

seats are missing in both compartment, I didn’t add them because

I planned to use the crew. About that, I added the legs to the driver.

- After

painting I’ll add the Bren gun and the Enfield rifles taken

from the spare box. The former will be stowed between the driver’s

compartment seats; the latter in the rear compartment.

Wheels

and tracks

- The

double guide teeth are solid. As for my S-Model Stuart tank, the

solid tracks were cut in sections and glued in place after having

divided the guide teeth with a file.

- Having

cut the track units in sections, I drilled the solid parts between

the bogey suspension springs before re-assembling them. Looking

at the photos while editing the review, now I think that a better

result could be obtained with thin metallic wire wrapped around

a stretched sprue segment. Too late…

Thanks

to Gianluca Trivero who shared one of his three kits in the box.

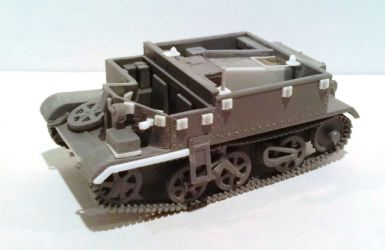

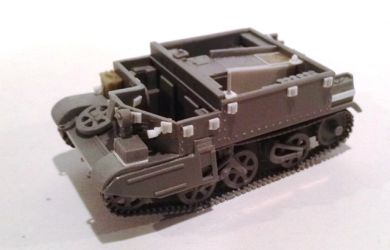

The IBG kits

These

kits need very few words to describe. When I saw the photos of the

mouldings for the first time I thought I was seeing 1/35 kits! Very

well detailed, this kit can almost be built straight out of the box.

Some details thickness look a bit oversized, but still look well.

A bit hard to achieve is a correct track assembly. I didn’t

use the template present in the box. The interior is well detailed

and a lot of items are given to fill the compartments.

Very little work was needed to have two carriers in Normandy: a Mk

II and a Mortar Mk II. About the latter, an easy conversion can be

obtained making the Mortar Mk I swapping the specific pieces. A specific

job was made to the mortar base, which lower side details need to

be thinned (the thickness on the edge and the blades which go in the

ground). I added some basic details:

Hull

- The

glacis overhangs the front plate a little. I made this with a thin

stretched sprue segment.

- As

already told, I chose to ignore the wall thickness, but the rear

compartment handrail is squared, which is not completely wrong.

It was used squared on the early production Mk I. I sanded it rounded.

- On

the front plate I added the starting handle access with a stretched

sprue segment.

- The

front towing points are plain and too thick. I drilled the holes

and thinned them before gluing on the glacis. Attention must be

paid because they are not identical and are not interchangeable.

- The

right side of the MG position had a narrow strip welded on the edge.

Also this was made with a thin stretched sprue segment. PSC has

this detail moulded on.

- Just

under this segment I added a little thin plastic trapezoid. It is

the shutter of a vision slot, missing in the kit.

- I

thinned the exposed fenders.

- The

Mk II single light received its wiring.

- I

also added the little lamps present on the Mk II front.

- The

Mk II skirts upper edge doesn’t have the gap and doesn’t

look well. I reshaped it and thinned the edges on my Mortar carrier.

To have something a bit different I made the Mk II without the skirts;

the exposed edge of the mudguards was made with thin plastic strips.

The steps in the skirts were sanded on the upper part, which were

not flat.

- The

rear steps are small and solid. I replaced them with thin metal

strips folded and cut to the shape.

- Also

my IBG carriers received the deep wading interlocks. On the UC two

of them are missing because they are placed where I have to glue

a couple of crew items.

Interiors

- As

for the PSC kit (see above) I corrected the engine cover. Here too

I lost the riveting row.

- On

the widened deck I had to add a new mesh, which is not a bad thing,

because IBG didn’t do a good job in depicting it. (Take a

look with a magnifier.)

- I

also added the inner shutters of the vision slots made with very

thin plastic sheet.

- I

added the missing shelves for the antenna bases because these small

parts can easily be lost.

- With

plastic round rods I made the two fire extinguishers of the “early”

brass cylinder type which were placed at the sides of the Bren gun

mount (these too with the handle not “T” shaped).

- In

the co-driver area I added the shelf for the 2” mortar.

- I

softened the corners of the padded seats

- I’ll

add the stowed Bren gun and Enfield rifles after having painted

the interiors.

- The

raised strip on the deck is too thick; the best thing to do is replace

it… I kept it as it is.

Wheels and tracks

- The

links pitch should be tighter. The effect is that they look too

much spaced. Anyway the tracks look well and I kept them as they

are, but for who is more finicky an aftermarket set is available.

- In

my kits the wheels spokes were almost joined by the (thin) flash

of the mould. I carefully cleaned them before I cut them off from

the sprue.

- A

careful job is needed to cut off the sprockets because the presence

of the sprue between the little sized teeth.

- I

didn’t use the template for the tracks, preferring to glue

them directly on the wheels set, adding a little sag on the upper

length.

Universal

Carrier:

Mortar

Carrier:

An

easy conversion: the AOP Mk III

I wished

to also have a Carrier with the Mk I skirts. As far as I’ve

seen up till now, with the British troops in Normandy the UC Mk Is

were rare. The Universal Carrier Mk Is looks to be more widely used

by the Canadian troops. For mine I opted for an AOP Mk III (the AOP

Mk I was based on the earlier Scout Mk I and the AOP Mk II on the

UC Mk I), although the Mortar Carriers Mk I (see for example T80222

or T167648) were used as well.

As far as I found 4,577 AOP Mk IIIs were made in two batches (T84621

- T88063 and T167832 - T168965). Photos taken in Normandy show the

usual deep wading kit, the absence of the ladder on the left side

and the inner antenna shelf. The AOPs were used not only by the Artillery

unit; they were also used by the Infantry units, as witnessed by the

AoS numbers. To make mine I made the same job already described above

and then:

- The

main difference between the other marks was in the engine cover,

which had a different air inlet layout. The “V” shaped

part was cut off and the holes closed with plastic.

- The

air inlet on the division plate were erased and the hint left at

the end filled with cyanoacrylate glue which fill very well the

little sinks.

- The

Mk III had a welded hull, so I erased the riveting.

- An

easy way to recognize a welded hull in low definition photos (were

the riveting is not well visible) is the raised lower edge of the

upper side plates. A simple plastic strip did the job.

- The

skirts are well done and need only to be thinned. If these are not

used the mudguards edge is correct as it is.

- As

far as I can tell, the Mk I rear bin is a millimeter too long and

the rack a millimeter too short. I shifted the engraving forward

and thinned the rack.

- The

Bren gun position was closed with a new flat plate, where I cut

the window. This was closeable with a sliding plate which could

lifted to see through.

- I

replaced the double lamps with a late type single one placed in

the middle of the glacis.

- Photographic

evidences shows the absence of the spare wheel on the glacis. Its

place was often used for boxes or soft items.On the rear shelf right

side and on the glacis there were two cable reels. I made them with

plastic and thin metallic wire.

- I

suppose there were other little differences, but I was satisfied

and I didn’t add other.

Decal

When I bought my kits, there were only two out of four kits in the

shop of my town: the Mk I w/ Boys rifle and the Mortar Carrier Mk

II. They were pretty good for my needs.

- Mk

I T78987, Red Army. It is correctly depicted.

- Mk

I CT112308, Loyal Edmonton Regt., 2nd Inf. Bde., 1st Cdn Inf. Div..

It is correctly depicted, the right light is missing and its place

is taken by a metallic box. The AoS number on the front is symmetrically

placed to the Divisional badge, the Boys rifle is not on the firing

position.

- Mk

I No WD Beute carrier. It is correctly depicted, but looks to be

unarmed.

- About

the following I didn’t find their photos:

-

Mk I T8873, 10th Pol Mounted Rifle Regt., 1st Pol AD. The WD

number is for a Mortar carrier Mk I

-

Mk I CT43054, 7th Recce Regt., 3rd Cdn Inf. Div., .

-

Mk I T17068, 5th Royal Hampshire Reg., 128th IB, 46th ID. The

suggested WD number falls in a Beaverette batch. Anyway, it

is only suggested in the instruction, being absent in the set.

- Mortar

carrier CT201944, 43rd Infantry Division, 43rd Recce Regiment.

If correctly depicted by IBG, this should be the first batch

based on the Mk II hull in the WD number sequence.

-

Mortar carrier T228174, 25th Uhlan Polish Regiment, 5th Polish

Infantry Regiment. The bison on a yellow background looks like

the badge of the 11th Armoured Division. The 25th Ulanow Wielkopolskich

was a Recce Regiment; the blue/green background is correct as

well as number 77.

Kit purchased

by author.

Conclusion

The comparison

between the kit makers doesn’t give us a winner. IBG kits, despite

their faults, are still great and look well with very little extra

detailing. As a wargamer kit the PSC kit is very good, simplified

but correct. A feature shared by both kit makers is the engine cover

section which is symmetrically sloped. I didn’t find photos

which show this engine cover type and I don’t know if it was

really used; anyway I modified it for my models to a type that is

surely correct. Surprisingly, some PSC details are better depicted,

like the rear steps, the engine deck mesh, the Mk II skirts and the

gunner position plates. For both, an aftermarket set with the engine

cover, PE upper hull plates and other little details would be useful.

The kits also offer a good base for easy conversions which only need

some plastic sheets and rods. At the end I think that the IBG kit

is certainly better detailed, but if your model is packed with different

sorts of stowage which hide the details and has a crew, the PSC kit

is, with a little elbow grease, a very good alternative.

IBG & PSC products

are available at

|